Goldman Plumbing is leading the way in water quality management.

With a focus on Legionella risk mitigation, we offer a complete and comprehensive service to best ensure your facilities water systems are healthy.

Our team are experts in identifying high risk areas of hot and warm water systems, water quality monitoring, water system disinfection and water treatment equipment maintenance and service.

Goldman Plumbing is a provider of Legionella Risk Management Plans to the Health Care and Aged Care Sectors.

A detailed site inspection is undertaken by a member of our water treatment team with the purpose of identifying areas or elements of a facilities hot and warm water systems that carry an increased risk of proliferating Legionella Bacteria.

These findings are presented in a report along with our recommended risk management control measures for your consideration.

All recommendations and control measures are based on best practice methods and adhere to State and National enHealth guidelines.

Goldman Plumbing are members of the Legionella Management Advisory Group.

Regular scheduled water samples are taken from a nominated number of a facilities water fixtures and sent to a laboratory. These samples are analysed to determine the number of Legionella colony forming units CFU per mL of water.

Once analysed the results are presented in a report to the facility.

Goldman Plumbing uses the data of these reports to create a profile of the facilities systems and water quality. This data is crucial for the management of Legionella within water systems.

Goldman Plumbing currently offers water quality sampling and monitoring throughout QLD, NSW, VIC and SA.

In the event of a water sample returning an elevated Legionella count, a water system sanitation/disinfection is required.

Goldman Plumbing offers this service to all facilities, including regional areas and ensures all sanitations are completed within the required time frames. Once completed sanitation documentation is provided for your records to ensure compliance.

Scheduled sanitations/disinfections are also suggested as preventative maintenance. This keeps water systems clean by removing bio film from the inside wall of pipes, fittings and valves.

Keeping water systems clean dramatically reduces the risk of legionella bacteria proliferating.

Under certain circumstances Water Quality Control Equipment may be required to help keep your heated water system healthy. This can be due to poor quality water feeding the system, incorrect system design, inappropriate material selection for the system or a number of other factors.

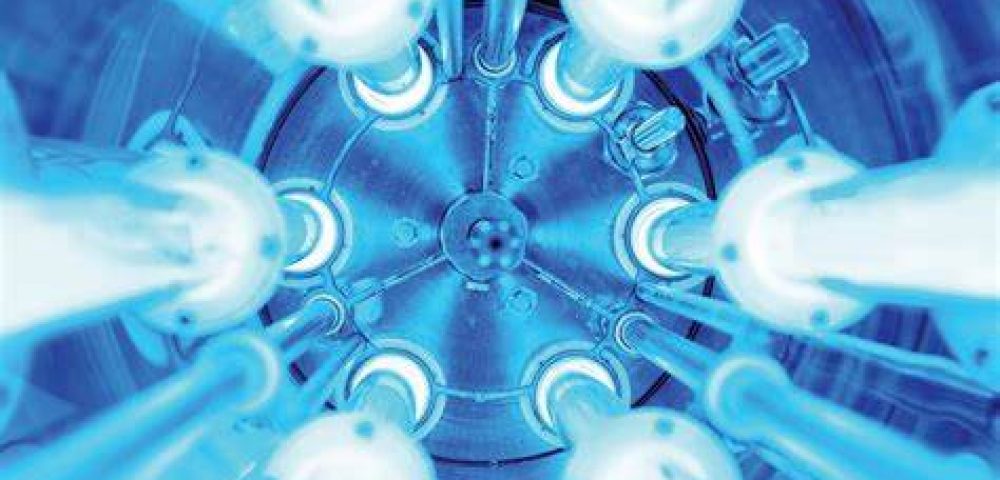

Water Quality control equipment can consist of temporary and permanent Chlorine dosing systems, Ultra violet light disinfection or copper/silver ionization.

If required, Goldman Plumbing can supply, install and maintain all Water Quality Control Equipment to manufacturers recommendations.

Regular Preventative Maintenance is essential to maintain a reliable and healthy hot or warm water system, reduce breakdowns and prolong the life of assets.

Goldman Plumbing offers a comprehensive Preventative Maintenance Program.

A site inspection is undertaken to document the existing hot and warm water plant and equipment and to determine the operational requirements of the facility.

A Preventative Maintenance Plan is then tailored to accommodate the facilities requirements.

Preventative Maintenance Programs are based on manufacturers recommendations and best practice standards and include a detailed asset service/inspection report upon completion.

Included with a Preventative Maintenance contract with Goldman Plumbing is our unique Asset Registry System. With this system all serviceable assets are labelled and numbered, with the asset details entered into our database.

This system allows for better management of your assets servicing requirements and history. It also helps track critical assets that may be at the end of their life expectancy.

In many cases a failed asset can be identified by on site staff allowing our service technicians to source parts and equipment prior to attending site, reducing any impact caused by the break down as well as saving on the associated costs.